CAD/CAM-enabled precision engineering represents the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to achieve high levels of accuracy, efficiency, and innovation in the engineering and manufacturing processes.

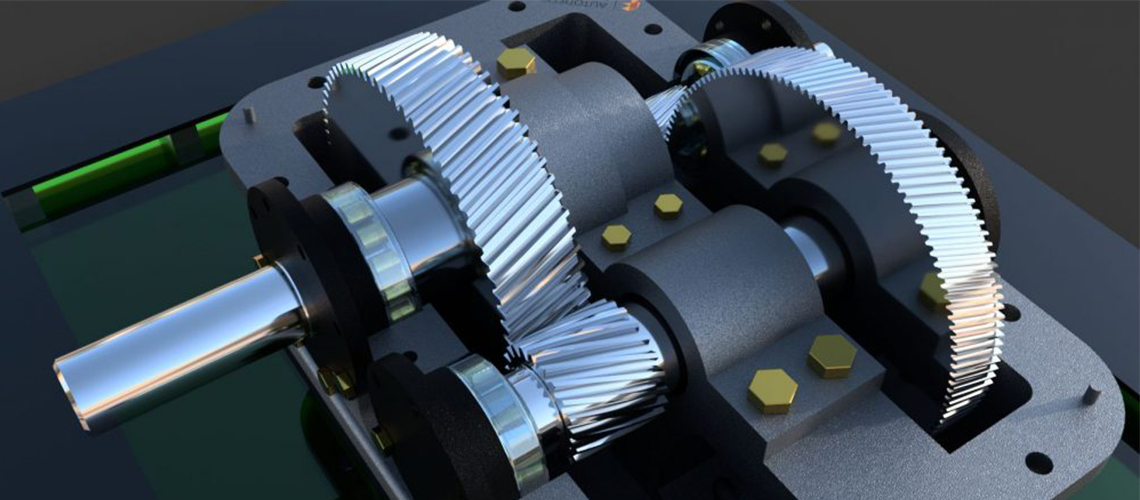

CAD software allows engineers and designers to create detailed digital models of components or products, enabling them to visualize, analyze, and refine designs before physical prototyping or production. This digital design data serves as the foundation for CAM software, which generates instructions for automated machinery to manufacture the components precisely according to the specifications defined in the CAD model.

The CAD/CAM process begins with the creation of a 3D model or 2D drawing using CAD software. Engineers can manipulate the digital model to optimize geometries, tolerances, and other design parameters to meet specific requirements. CAD tools also facilitate simulation and analysis, allowing engineers to evaluate factors such as stress, thermal performance, and fluid dynamics to optimize design performance and reliability.

Once the design is finalized, CAM software generates toolpaths and machining instructions based on the CAD model. This involves specifying cutting paths, tool selections, feed rates, and other parameters required for manufacturing. CAM software optimizes these instructions for efficiency, minimizing material waste and machining time while maximizing precision and surface finish.

The integration of CAD/CAM technologies enables precision engineering across various manufacturing processes, including machining, milling, turning, laser cutting, additive manufacturing, and more. By automating many aspects of the design and manufacturing workflow, CAD/CAM systems reduce errors, improve consistency, and accelerate time-to-market for new products.

Furthermore, CAD/CAM-enabled precision engineering facilitates design iteration and optimization, allowing engineers to quickly explore alternative designs and manufacturing strategies to achieve the desired performance and cost objectives. This iterative approach fosters innovation and continuous improvement, driving competitiveness and success in today’s dynamic market landscape.

In summary, CAD/CAM-enabled precision engineering revolutionizes the engineering and manufacturing processes by leveraging advanced digital technologies to design, simulate, and produce components with exceptional accuracy, efficiency, and reliability. By embracing CAD/CAM systems, companies can unlock new opportunities for innovation, customization, and competitiveness in the global marketplace.