Inspection fixtures design and manufacturing is a crucial aspect of quality control in manufacturing processes, ensuring the accuracy and consistency of dimensional measurements and inspections of components and assemblies. These fixtures are custom-designed tools used to securely hold and position parts during inspection, providing repeatable and reliable measurement results.

The process of designing and manufacturing inspection fixtures begins with a thorough understanding of the inspection requirements and specifications. Engineers collaborate closely with quality control experts and clients to determine the critical features, tolerances, and inspection methods needed for accurate part verification.

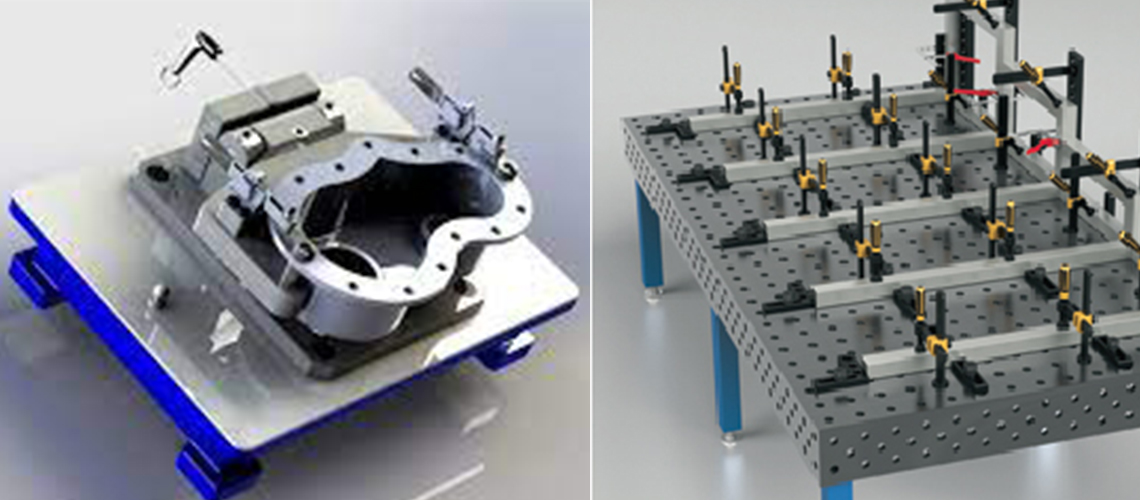

Based on this information, detailed blueprints or CAD models are developed to guide the fabrication process. The design of inspection fixtures focuses on providing precise location and orientation of the part to be inspected, as well as easy access for measurement devices such as CMMs (Coordinate Measuring Machines) or gauges.

Fabrication of inspection fixtures involves the use of advanced machining and fabrication techniques to create robust and precise fixtures capable of holding parts securely and repeatably. CNC machining, milling, grinding, and additive manufacturing technologies may be employed to shape, cut, and assemble fixture components from materials such as steel, aluminum, or composite materials.

Precision is critical throughout the fabrication process to ensure that the inspection fixtures meet tight tolerances and align accurately with the inspection specifications. Skilled technicians meticulously inspect and test fixture components to verify dimensional accuracy and compatibility with measurement equipment.

Inspection fixtures may incorporate various features and mechanisms to enhance functionality and usability, such as adjustable clamps, locating pins, datum surfaces, and reference features. These features enable efficient setup and alignment of parts for inspection, reducing measurement uncertainty and ensuring consistent results.

Once fabrication is complete, the inspection fixtures undergo comprehensive testing and validation to ensure optimal performance and reliability. This may involve conducting measurement studies using calibrated reference parts to verify fixture accuracy and repeatability.

In conclusion, inspection fixtures design and manufacturing play a critical role in maintaining quality and consistency in manufacturing processes. By leveraging innovative design and fabrication techniques, companies can create custom fixtures tailored to their specific inspection requirements, ensuring accurate and reliable measurement results, and driving competitiveness and success in today’s demanding market.